Interviews

We interviewed Teijin Nakashima Medical, a company that develops, manufactures, and sells medical devices such as artificial joints, bone joint materials, and spines, on why they decided to introduce ACCRETECH measuring instruments and what their impressions are.

- Teijin Nakashima Medical Co., Ltd.

- Teijin Nakashima Medical Co., Ltd. General Manager, Production Department Yuichi Shimizu

- Teijin Nakashima Medical Co., Ltd. Section Chief, Inspection Division, Production Department Akikazu Miyata

- Teijin Nakashima Medical Co., Ltd. Chief, Production Engineering Department Rikito Ishii

- The company started expanding into the medical field in 1987, and later established a medical business unit within Nakashima Propeller. In 1994, the company began selling artificial joints and spun out to form Nakashima Medical Co., Ltd. in 2008. After that, it began developing and selling the world's first vitamin E enhanced ultra-high molecular weight polyethylene "Blend-E" for artificial knee joints. In conjunction with the capital tie-up with Teijin Co., Ltd. in 2015, the company name was changed to Teijin Nakashima Medical Co., Ltd. Currently, the company develops, manufactures, and sells medical devices such as artificial joints, bone connecting materials, and spines.

- Main Office/Factory: 688-1 Joto-Kitagata, Higashi-ku, Okayama 709-0625

https://www.teijin-nakashima.co.jp/

Please give us an overview of your business.

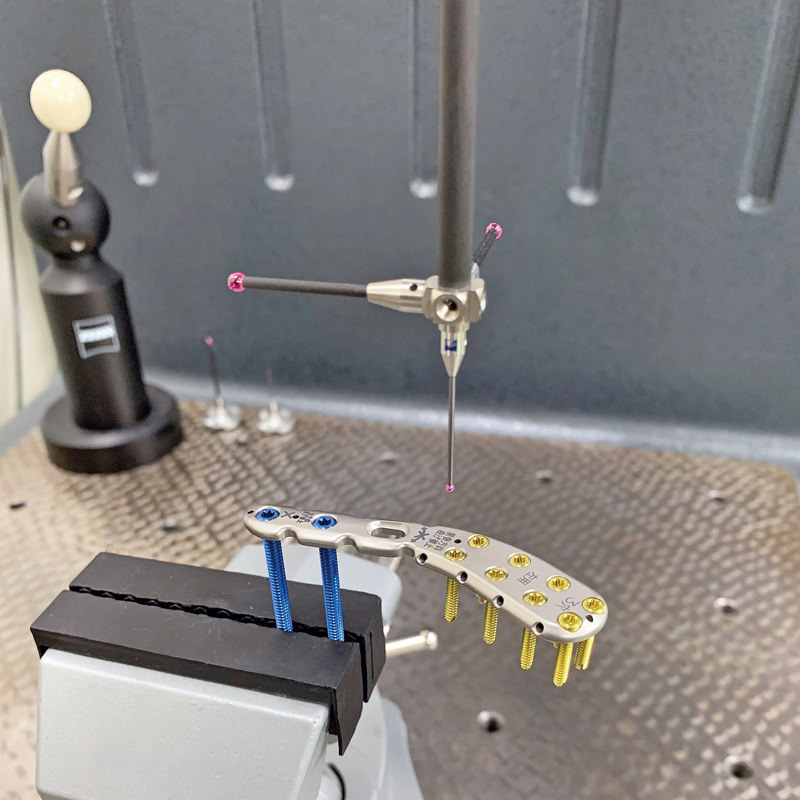

Shimizu: We develop, manufacture and sell artificial joints, bone connecting materials, and spinal fixation systems. In the artificial joint business, we develop total replacement types mainly used in patients with rheumatism and osteoarthritis, and in the bone connecting materials business, we develop plates, screws, and cables that connect bones in the event of fractures. In the spine business, we develop spinal fixation systems to be used in combination with spinal fixation surgery in the event of spinal canal stenosis, spinal slip disease, trauma, and other spinal-related issues. Because artificial joints originated in Western countries, overseas manufacturers generally possess a higher share of the market and are ahead in product development. However, in 2010, our company became the first in the world to significantly improve the wear resistance and oxidative degradation of the polyethylene plate that acts as cartilage in artificial joints by adding vitamin E. Although our only reference is simulation data since the product has only been on the market for a few years, we project that it has a service life of more than twenty years when the general average service life of other products is ten to fifteen years.

How is Teijin Nakashima Medical different from overseas manufacturers?

Shimizu: Overseas manufacturers primarily focus on mass production, but we place emphasis on high-mix, low-volume production. Because different surgical procedures and ways of thinking require different shapes and functions for surgical instruments, we sometimes provide products tailored to a specific doctor or hospital. We excel at developing original products that meet the individual requests of medical practitioners.

How did you first come to introduce ACCRETECH’s measuring instruments and which ones do you currently use?

Shimizu: Our relationship with ACCRETECH began in 2004 when we purchased a roundness measuring instrument. At the time, we were launching artificial hip joint products and purchased ACCRETECH’s measuring instrument in order to measure bone heads.

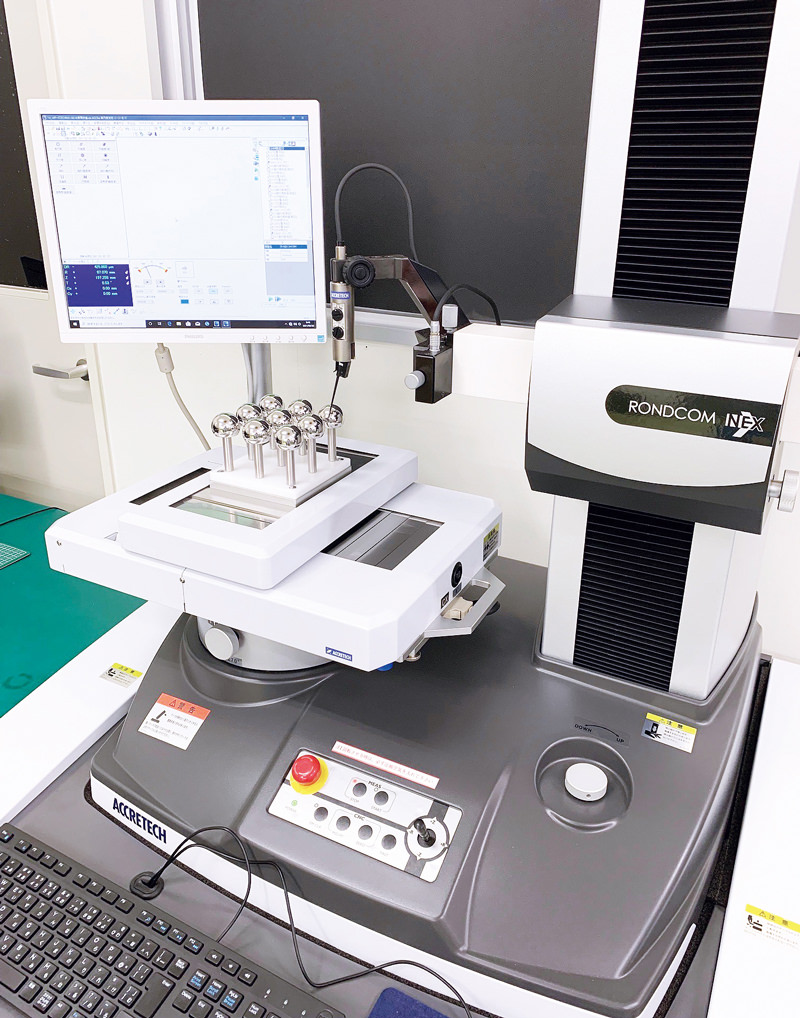

Miyata: The Femoral bone head needs to be as perfect a sphere as possible in order to reduce wear on the ultra-high molecular weight polyethylene plate (artificial cartilage) at the joint. It is an extremely important component that requires high processing accuracy down to the μm, which is why we adopted ACCRETECH’s roundness measuring instrument. For the part of the hole that joins the bone head and stem, in addition to measuring the roundness with RONDCOM 43C and RONDCOM NEX, we measure straightness using DuraMax. We introduced RONDCOM NEX last year because its previous-generation model RONDCOM 43C was convenient for our needs.

We distribute a large number of bone heads every month, but because RONDCOM NEX can measure about nine bone heads simultaneously, we have been able to reduce labor time considerably compared to our conventional method of measuring one at a time. Moreover, once the RONDCOM NEX is set up it automatically measures products, so this helps to free up workers during that time.

Do you have any expectations for ACCRETECH?

Miyata: We have had ACCRETECH service personnel come on several occasions, and I have the impression that they took great care in dealing with our issues. In addition, ACCRETECH provides maintenance once every three years, so we have experienced no problems in terms of after-sales service. Ishii: In terms of measuring instruments, I want a product that can be programmed more easily. At present, the products that require programming as needed are minimal, but considering such products may increase in the future, I want a product that can be easily programmed, including not only roundness measuring instruments but also 3D CMMs. Shimizu: In recent years, there have been many non-contact measuring instruments that use lasers, but the products we handle include mirror surfaces as well as materials that absorb lasers like ultra-high molecular weight polyethylene, which in many cases cannot be measured with a non-contact type measuring instrument. Processing with spray to enable laser measurement is not an option either, because our products are implanted in the human body. However, we still want to use a nondestructive method of measurement. It would be great if ACCRETECH could make a device that could perform non-contact measurement of mirror surfaces and resin products, measure both shape and surface texture with one machine, and even determine whether the product quality is good or bad.

What businesses will Teijin Nakashima expand to in the future?

Ishii: The best way to make artificial joints is to customize them based on the patient's CT scan. Currently, there are many mass-produced products classified by size on the market, but recently the country as a whole has been pushing for custom-made as being the best option. As we mentioned at the outset, our company excels at developing original products that meet the individual needs of our customers, so we will expand these fields further. That will require us to aim for even better accuracy, and we hope to continue making custom-made products using ACCRETECH’s measuring instruments.

Tokyo Seimitsu’s thoughts after speaking

Teijin Nakashima Medical has undertaken a major challenge to support longer healthy lives among the elderly in Japan, a country with high life expectancy. During the interview, we received many requests such as "Is it possible to measure X?" and "We want a measuring device that can do Y," and we could really sense how serious the company is about future product improvement and development. We felt that this spirit has led to their persistence and development in the implant products business, which demands one of the highest levels of accuracy among medical products. ACCRETECH will continue to develop our measuring instruments so that we may further contribute to Teijin Nakashima Medical’s product manufacturing.