Executive Interviews

Nabtesco Corporation is a holding company founded in 2003 by Teijin Seiki Co., Ltd. and NABCO Ltd. following the formation of their business partnership in the hydraulic equipment business. With a primary focus on motion control technology, Nabtesco is a manufacturer with the world's top market share and top domestic market share in a wide range of business fields related to air, land, and sea.

About Nabtesco

Yoshida: First, could you please tell me about Nabtesco’s business operations?

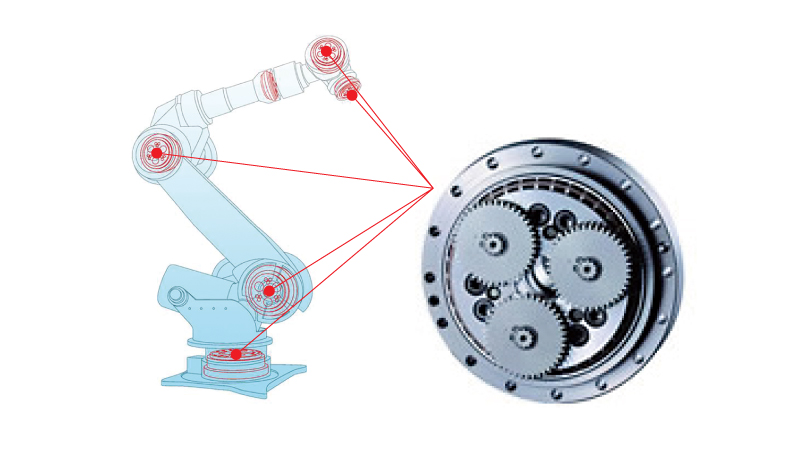

Shimizu: Nabtesco Corporation is a holding company founded in 2003 by Teijin Seiki Co., Ltd. and NABCO Ltd. We have achieved steady growth by expanding our businesses in a wide range of areas, with "motion control technology" that precisely moves and stops objects at our core. Our extremely diverse business scope includes industrial robots, aerospace, rail, construction machinery, marine, commercial vehicles, automatic doors, and food packaging machines. The precision reducer is a part that supports the agile and precise movement of industrial robots operating in automotive production lines. For many years, Nabtesco has honed its proprietorial technology for reducers offering high precision, high rigidity, and high durability.

Yoshida: We are also focused on the pursuit of high precision, high rigidity, and high durability. What do you think is important to achieve these three?

Shimizu: The dimensional accuracy and surface quality of the parts that determine product performance. In other words, the important point is ultra-precision finishing technology such as grinding and polishing.

For example, the servo valves of FCAS (flight control actuation systems) in the aircraft business, which I have been involved in for many years, require submicron accuracy locally.

Because the flaps of an aircraft's main and tail wings (the movable parts of fixed wings) must hydraulically control the orientation of a large aircraft with a stroke of only a few tens of centimeters of the hydraulic actuator, the servo valves at the heart must be built with considerable precision. In the past, machine tool machining accuracy was limited, so the individual skills and experience of workers were relied on, but now we can use the power of our evolved high-precision machine tools and ACCRETECH’s measuring machines to guarantee high precision, high rigidity, and durability.

- Nabtesco Corporation

- General Manager Production Innovation Division

Exective Officer - Isao SHIMIZU

How did Nabtesco and ACCRETECH’s relationship start?

Yoshida: You introduced ACCRETECH’s measuring equipment because you wanted to perform auto-sizing measurement when grinding the servo valves you just mentioned, right? I think you decided to purchase our measuring machines because you needed to secure submicron-level processing accuracy.

Shimizu: That's right. Thanks to ACCRETECH’s help to measure servo valves for aircraft during the machining process, we were able to secure high accuracy.

Recently, we adopted ACCRETECH’s CMM in an automatic processing cell for core components of our precision reducer for industrial robots. In the case of industrial robots, the positioning accuracy of the tip is less than 0.1 mm for a size of 3 m. Therefore, I think you can imagine just how accurate the machining accuracy of some core parts of precision reducers needs to be. We can ensure quality of such manufacturing processes because ACCRETECH’s machines are taking care of in-line automatic measurement.

In addition, ACCRETECH’s unique feature is that your machines have high affinity with automatic processing cells; making them easy to integrate.

I would like to once again express my sincere gratitude to ACCRETECH for supporting the foundation of our manufacturing from many angles.

Yoshida: On the occasions I’ve been to your plants I really sensed Nabtesco’s strong commitment to accuracy. I definitely got the feeling that, just like ACCRETECH, Nabtesco places importance on high precision and high reliability.

Nabtesco’s secret behind top market share

Yoshida: Many of your products make up the top market share, don't they? What's the secret to that?

Shimizu: Currently, many Nabtesco products occupy a high market share, and our strategy varies depending on the business and product.

Because we are involved in such a diverse range of businesses, the scale of each business is not large, and our resources are limited. By thoroughly analyzing what strengths we should emphasize in what areas by considering not only our customers but also our customers’ customers, then reflecting this knowledge into our strategies and concentrating our limited resources, I think we have achieved the high market share we enjoy today.

As fortune would have it, most of Nabtesco's customers are major Japanese or overseas companies, and I believe our non-stop efforts to create and provide high customer value to them have led to a high market share.

This customer value, of course refers to the technological advantage of the product itself, but I also believe much of that value is in the competitive advantage of QCD in manufacturing. We are very particular about delivery time and quality.

Yoshida: Customer satisfaction is important to establish market share, isn't it? You also need to differentiate yourself from competitors through applications, proposals and so forth. In addition, I think that it is important whether reliable results can be presented firmly in the field even if there is no big difference with the competitor insofar as specifications listed in catalogs.

Shimizu: That's right. In the past, when we visited a car manufacturer that is a customer of a robot manufacturer, we were shown data comparing our precision reducer for industrial robots with that made by other companies, and our products were evaluated as seven to eight times more durable than other companies. As you said, even if the specifications in the catalog are the same, I feel that customers are paying close attention to the visible results on a working level.

Yoshida: ACCRETECH was also evaluated by our car manufacturer customer that our measurement error in temperature change was the most reliable compared to our competitors’ machines. We also believe that if you make something good, the customer will always notice.

- Tokyo Seimitsu Co., LTD

- President & CEO

- Hitoshi YOSHIDA

About Nabtresco’s work

Yoshida: Please tell us about the work of your Monozukuri Innovation Promotion Division.

Shimizu: The Production Innovation Division consists of three sections; the Manufacturing Engineering Dept, Procurement Planning Dept, and Environment & Safety Dept. The Manufacturing Engineering Dept is divided into the Manufacturing Engineering Group, which is responsible for the development of high-automation and proprietary production technologies, and the Production Management Group, which promotes "mieruka" (visualization) utilizing ICT (IoT/AI).

In order to keep up with the current IoT/AI trend, we are considering introducing these to our operations, but we believe that it is difficult to form an IoT/AI platform because the production volume and production form of each of our “companies” (plants) are very different due to the fact that Nabtesco is an aggregation of different industries. Therefore, we consider IoT/AI to be a mere tool, firmly examine what each of our plants wants to do, and transition to ICT with a so-called "small start" by introducing devices that meet each purpose and need. We are currently trialing this activity.

Yoshida: Is there something you place particular importance on in your work?

Shimizu: Communication is key, right? We think that the role of the Manufacturing Innovation Promotion Division as a head office organization is to provide new solutions to our respective plants’ manufacturing sites. As a head office organization, it is important to discuss many times about solutions to achieve management goals and the reforms and improvements that each plant wants to achieve, and to nail down the measures to be implemented in a way that is mutually-satisfying. I think this is the most important type of communication.

I was plant manager for about four years, and I placed great value on close communication with the shop floor back then too, but in my current position in a head office organization, a higher level of communication is necessary as we must discuss matters with a collection of employees from different industries with diverse ways of thinking.

Yoshida: Just as you say, I also believe communication is important. ACCRETECH also adopts an internal company system, but we are working to integrate areas that are currently independent. It is important to have an organization that has a common manufacturing philosophy even if each area’s products differ. It would be nice if there was interaction between the plants, but we don't have that kind of structure yet either. I'm sure each separate entity has common ground regarding perspectives and concerns. It would be ideal to integrate the good points of each to promote good manufacturing.

Shimizu: There is a lot to gain from different industries working together. I've said that it's hard to build a platform in terms of production management, but in terms of production technology, we can say “Let's use that technology here, let's combine that technology there,” and so on. Occasionally, it is also possible to create new production technologies through synergism.

Production initiatives

Yoshida: Nabtesco promotes a shift toward IoT and automation, doesn’t it?

Shimizu: Yes. We are currently promoting high automation. However, this is only feasible for a limited number of manufacturing processes. In processes such as assembly and inspection, we still rely on the skills of workers, and we think that the coexistence of worker skills and automation is desirable for the future. The only process easy to promote high automation for is machining, so we are building a system that combines machine tools, measuring machines, and robots. In order to further improve the competitive advantages of QCDE, it is necessary to have a mechanism that can guarantee quality within each automated production process. For this reason, the measurement data of the intermediate processes is digitized, so that it can be used for automatic determination and statistical quality management. In addition, as automation advances, operators will be absent on the shop floor, meaning it will be necessary to have the ability to predict (monitor) equipment abnormalities, and that is where we would like to make effective use of IoT. We are currently preparing IoT for equipment preventive maintenance.

Yoshida: We are also actively proposing to our customers that they introduce measuring machines into their production lines. Our measuring equipment must be automated and IoT-equipped in order to contribute to optimal production. Currently, we are promoting labor-saving by automatic measurement, data management, and measuring machine management. In addition, since we have an engineering department, we undertake individual requests of our customers as a whole package. Our two companies’ respective sense of direction match perfectly, don’t you think?

Future outlook

Yoshida: Please tell us what you see on the horizon for Nabtesco’s business.

Shimizu: With regard to our future outlook, we are anticipating long-term growth for many of our businesses despite repeated fluctuations in demand, so we are firmly envisioning what our manufacturing should be like in 2030 and steadily implementing measures to further improve our competitive advantage in terms of QCDE. Our collaboration with ACCRETECH will become even more important in the future, considering the reality that we are generating high-quality customer value is in the market especially in the industrial robot and aviation businesses.

Yoshida: As your partner on into the future, what are your expectations of ACCRETECH?

Shimizu: I think we will continue to turn to ACCRETECH for in-line measurement of mass production lines for our precision reduction gears used on industrial robots and ultra-high precision measurement of FCAS servo valves in our aircraft business. Additionally, we manufacture core parts for construction machinery, rail, and commercial vehicles, in-house, so we will promote in-line measurement for the future. Amongst this, I would like ACCRETECH to aim for even higher ultra-high precision measurement and a measurement system that can control machine tools. We will continue to exchange information regularly to communicate our needs. Thank you, as always, for your support and cooperation.

Yoshida: Of course, responding to tough demands will become our strength and open up the next chapter for us at an even higher level. We also truly value customers who voice their honest options. Please keep on sharing your requests without reserve as we will do everything in our power to fulfill them.

Nabtesco Corporation

Nabtesco Corporation is a holding company founded in 2003 by Teijin Seiki Co., Ltd. and NABCO Ltd. following the formation of their business partnership in the hydraulic equipment business. With a primary focus on motion control technology, Nabtesco is a manufacturer with the world's top market share and top domestic market share in a wide range of business fields related to air, land, and sea.