Introducing RONDCOM CREST FiANA

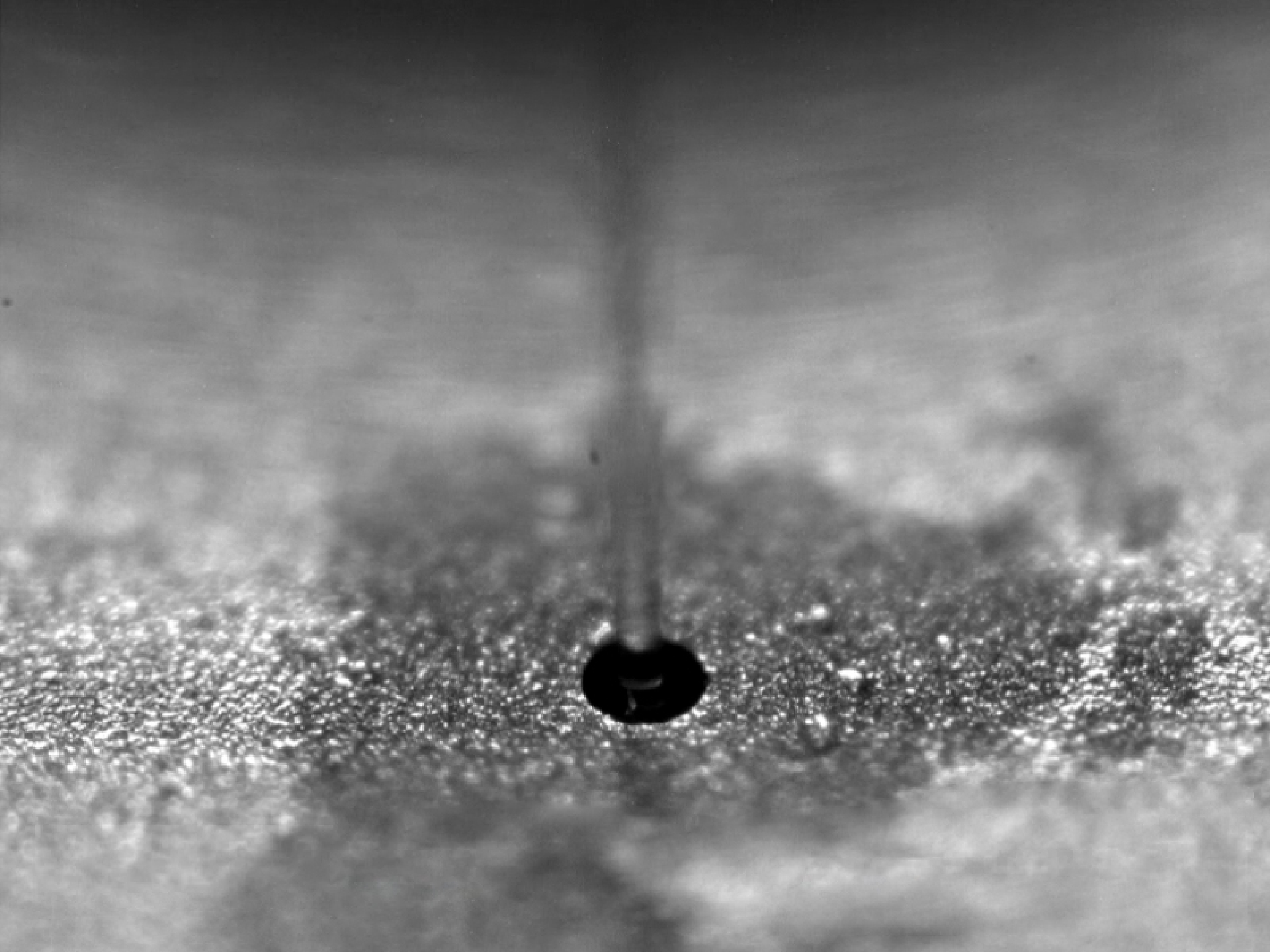

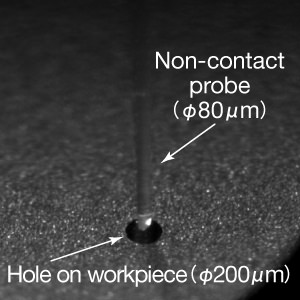

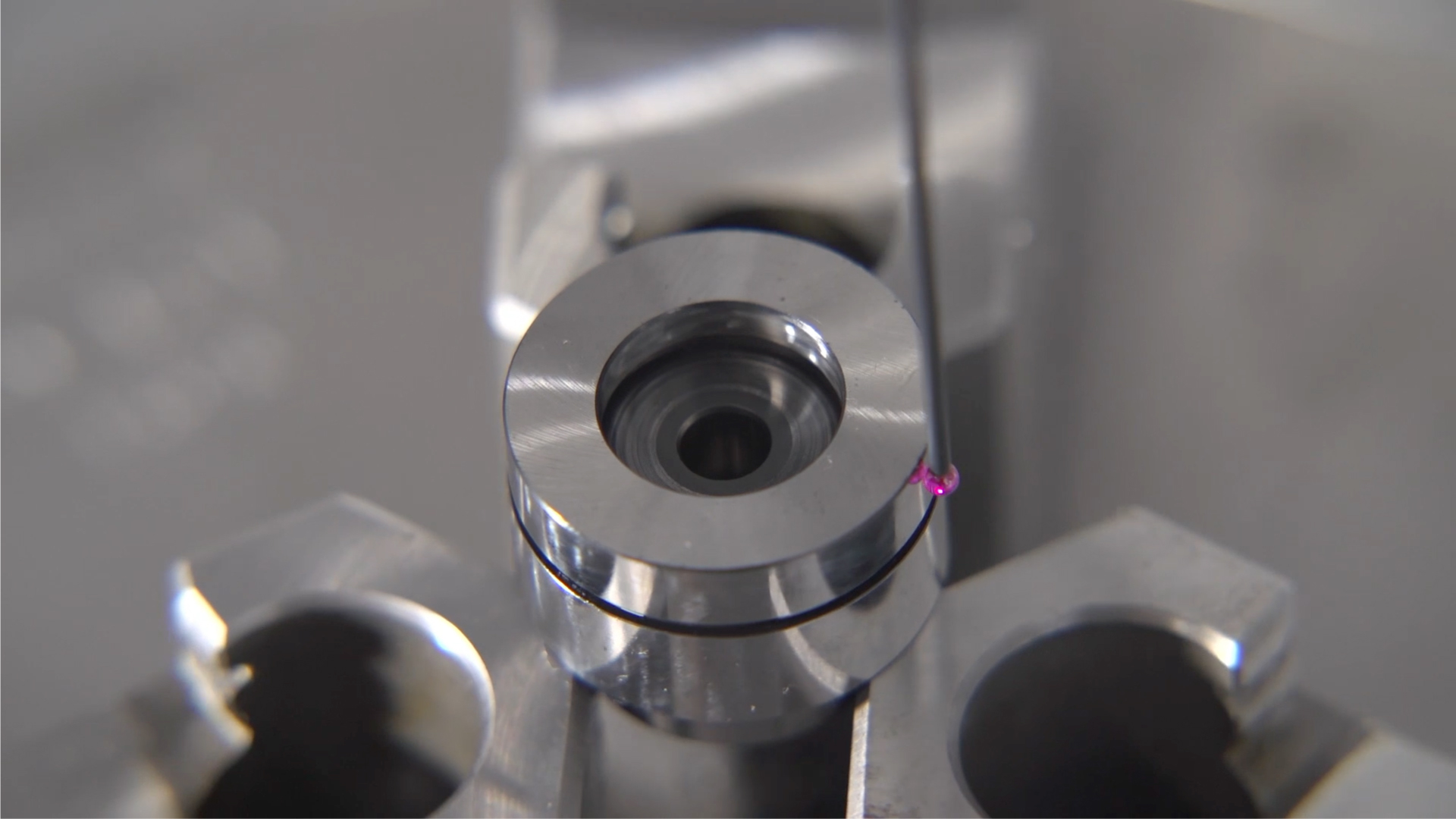

A new product created by applying the base technology of RONDCOM CREST, a roundness and cylindrical measuring instrument with the world's highest level of accuracy. An ultra-thin probe enables non-contact measurement of ultra-small holes down to 0.15 mm.

Product Summary

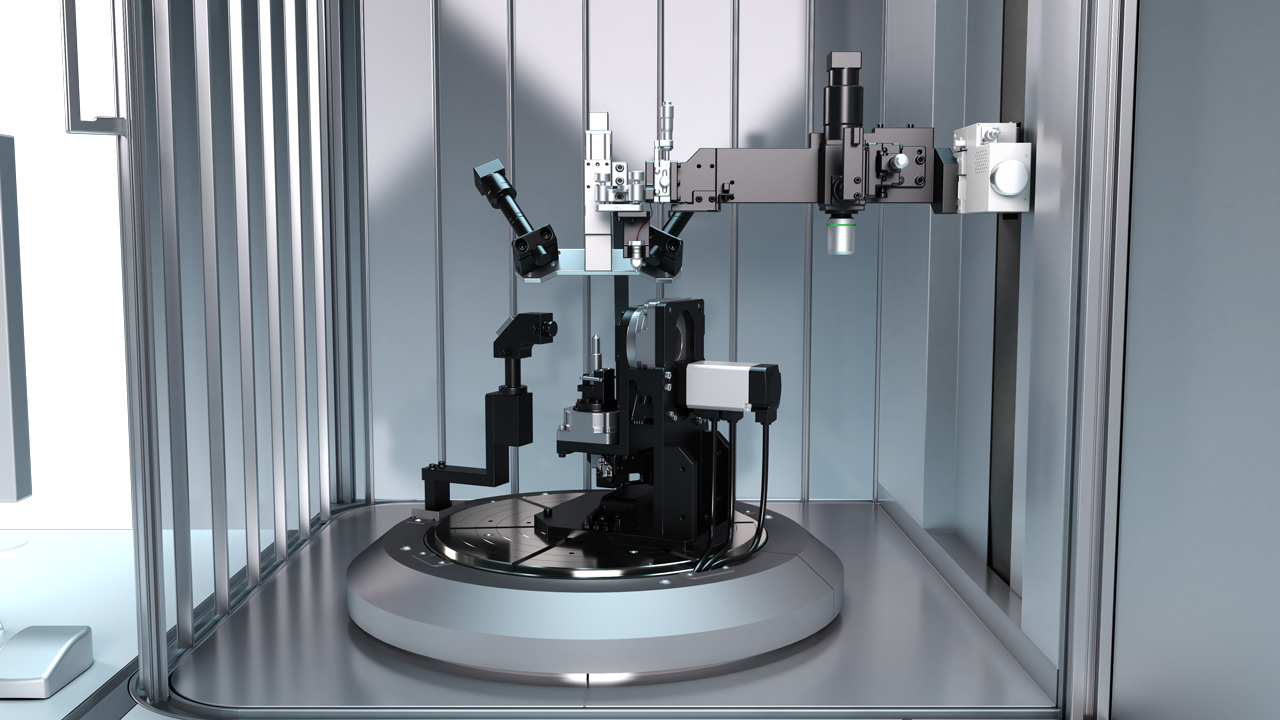

Ultra-high Accuracy Roundness/Cylindrical Profile Measuring Instrument

Ultra-high precision at the world's highest level, realized by a newly developed drive and guide systemPatent pending

RONDCOM CREST is equipped with a newly-developed mechanism that consolidates all the tradition and technology of ACCRETECH on the column Z axis and the drive unit R axis. The drive system adopts a new method that combines the non-contact and low vibration linear motor drive technology that has earned a strong reputation among customers over the years in our surface roughness and contour measuring machines with a newly developed original Alignment mechanism. In addition, the guide system inherits the non-contact support technology using air bearings cultivated for years in CMMs then applied to the RONDCOM 60 series, in a newly developed mechanism that upgrades the air bearings to meet the low vibration specifications dedicated to RONDCOM CREST. Combining these drive and guide methods significantly improve rotation accuracy, alignment accuracy and straightness of each axis, realizing world-class ultra-high accuracy suited for a reference machine. In addition, since both the drive and guide systems have a non-contact structure, there is no wear on the guide section, maintaining stable high accuracy over a long period of time. ACCRETECH presents RONDCOM CREST FiANA, a new measuring instrument created by equipping an ultra-thin probe on RONDCOM CREST, which boasts one of the highest accuracies in the world. FiANA enables non-contact measurement inside ultra-small holes down to 0.14 mm.

Workpiece observation camera system

Non-contact probe

Workpiece alignment camera system

Workpiece alignment stage

High-precision rotary table

Workpiece alignment camera system

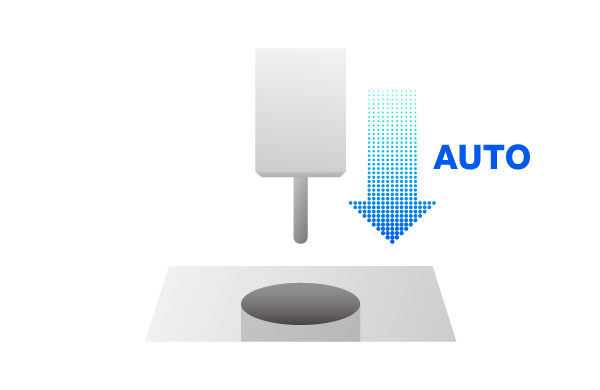

Equipped with an automatic probe insertion system

RONDCOM CREST is equipped with an automatic probe insertion system (patent pending), making measurement easy for anyone.

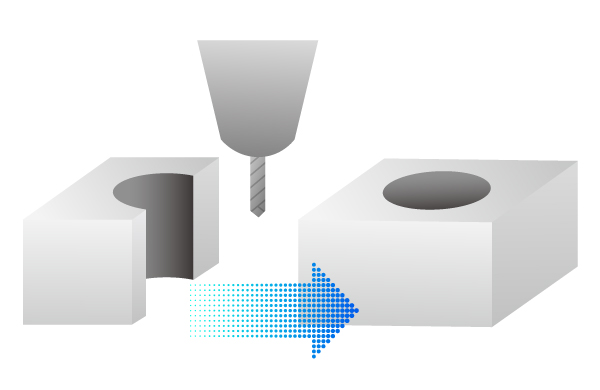

No need for cross-cuts

There is no need to prepare cross-cuts. Measurement can be started right away.

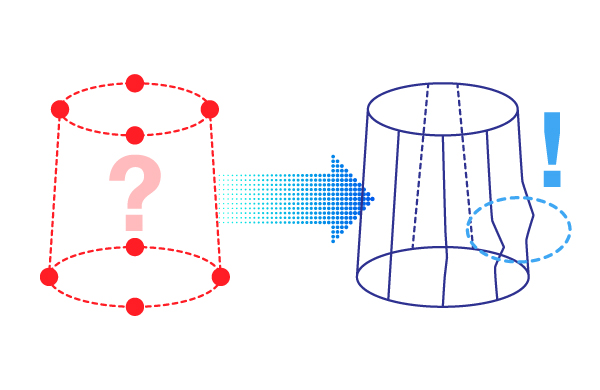

bundant information with scanning measurement

A switch from Single point measurement to scanning measurement offers an abundance of information from point clouds, enabling detailed analysis.

Specifications & Features

A non-contact sensor performs automatic measurements of ultra-small hole Inner wall surfaces

Automatic probe insertion system

Automatic probe insertion system (details)

No need for cross-cuts

A switch from single point measurement to scanning measurement offers an abundance of Information from point clouds, enabling detailed analysis.

Measurement example: Hole with 0.2 mm diameter and 0.8 mm depth

RONDCOMCREST FiANA - EYE

The Developers' Perspectives

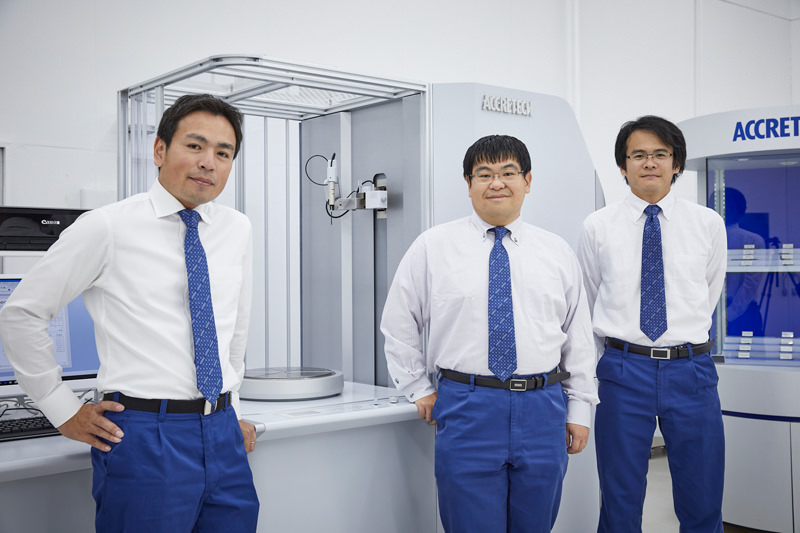

RONDCOMCREST FiANA is a new 2021 model applying the base technology of the ultra-high accuracy RONDCOM CREST (released 2019), customized to perform internal measurements of extremely small holes with diameters down to 0.15 mm. We talked to the development team that oversaw this one-of-a-kind product development about key development points and future outlooks.

Hideki Morii

Sub-Leader

Surface & Form Group, Engineering Division

Metrology Company

Hiroaki Kimura

Supervisor

Surface & Form Group, Engineering Division

Metrology Company

Katsufumi Moriyama

Surface & Form Group, Engineering Division

Metrology Company

ーPlease tell us the features of the new model.

Moriyama:The new model adds new features to the existing RONDCOM CREST, an instrument that measures roundness and cylindrical profiles at the world's highest level. RONDCOM CREST measures most kinds of axes and holes such as those in mechanical components. It uses a contact-type probe to check components such as bearings for accurate roundness, or holes to ensure they are not distorted or tilted internally even if their entrance is perfectly circular. The new FiANA adopts a non-contact probe that is extremely thin for measurement, making it possible to illuminate the interior face of extremely small holes with light and read the reflected data.

The ultimate level of positioning accuracy offered by RONDCOM CREST was the key element of the new model's development. This is because FiANA allows a 0.08 mm, ultra-fine probe the size of a strand of hair to be inserted in holes as small as 0.15 mm in diameter, which means measurement is not possible if the insertion position is displaced by even 0.02 mm.

ーPlease tell us the motivation behind this development.

Moriyama:A manufacturer of automobile engine parts approached us, seeking a way to ensure perfect roundness of tiny holes in a particular component in order to increase fuel efficiency. No method to measure internal details of such tiny holes existed until now, and I think the customer previously checked only what was visible through magnification or actually cut the workpiece to measure it with a contact-type measuring instrument.

ーWhat other fields do you think need this technology?

Kimura:There are many companies out there that excel at making tiny holes. However, there are hardly any that can accurately measure the internal precision of such holes. It's safe to say that such measurement isn't possible without FiANA. I don't think people even considered the possibility of measuring such small holes before, and they were resigned to the idea that it wasn't an option. It would be great to be able to find customers with such needs.

Morii:I'm sure there's a broad market out there, such as for medical devices, fiber optic communication, and semiconductors. Creating and measuring are two critical aspects of monozukuri (manufacturing). Repeating this cycle of creating and measuring can improve product performance and ultimately lead to breakthroughs. It would be a shame if innovation wasn't happening just because people gave up on making something because they assumed they didn't have a means of measuring it. I hope we can use ACCRETECH's technology to offer people like that a way to move forward.

Moriyama:In the future, I hope we can find a way to measure diameter as well.

ーWhat difficulties did you face during development?

Moriyama:The biggest challenge was adjusting the lighting. RONDCOM CREST has fantastic positioning performance, but that's meaningless if it can't see. Trying to operate with a view through the camera wasn't working, but we were able to adjust lighting and image processing through trial-and error with our software manager Mr. Kimura.

Kimura:There were three challenges we struggled with from a software development perspective. The first was to minimize the number of operations and make them straightforward for the sake of user-friendliness. The second was to give the new model the versatility to satisfy other customers' requirements with minimal customization. The third and most demanding challenge was to reconcile the first two.

Moriyama:Both software design and mechanical design demand speed, so we had meetings practically daily.

Morii:It was tough, but I think our team's excellent communication was the biggest key to our success. I think it would have taken forever if each member only cared about their area of expertise.

ーMr. Morii, was there anything difficult for you as the project leader?

Morii:When we were discussing how to align the hole and probe on the same axis, the conversation went in the direction of "wouldn't we be better off trying a new approach rather than the one we have now?" As project leader, deciding on such a change in direction is terrifying because you think about what would happen if it failed. But when I was having such concerns, Mr. Moriyama immediately presented me with logical data that ensured another method would work, helping me to reach a conclusion. As a result, the mechanism became simpler with easier customization. We were able to file many patent applications too, which was a relief.

Kimura:When we brainstormed together, ideas would lead to more ideas, kind of like an improv game where we all tried to one-up each other. I can say with confidence that our team has amazing communication skills.

ーWhat are your goals for the future?

Morii:A development team is all about challenging ourselves to attempt new things, and if it doesn't work out, we can always immediately turn back. Even if we fail, we write it off as a learning experience and try again. I think it's important to keep cycling through this process at a swift pace. I want to establish the sentiment within our team that we should actively encourage new attempts and that failing is much better than doing nothing at all.

Kimura:I want to make software that I can be proud of. I've had this goal since I joined ACCRETECH.

Moriyama:I always want to find joy in working on development and rising to a challenge. Rather than take failure in a negative way, I want to keep trying with the belief that success awaits at the end of a series of failures. I also want other members on my team to feel a project they were involved in was enjoyable and meaningful. Our team has a culture of acknowledging one another so I hope we can continue taking on new challenges as one.

Making Measurement that Seems Impossible Possible

R-CREST/FIONEC enables measurement of ultra-small holes that no one managed to accomplish until now. ACCRETECH will continue to take on new challenges in order to eliminate situations where manufacturing sites assume that they can't make something because there's no way to measure it.

Other Products

View All Products