NEV e-Motor

With the increase in the production ratio of electrifiedc vehicles such as HEVs and BEVs, there are significant changes being made to vehicle unit configuration and the development/production methods thereof. In particular, the market for NEV-specific components such as drive motor units, inverters, and batteries, is predicted to undergo further growth. ACCRETECH proposes the optimal solutions to meet the changing needs of customers from the development to production of NEVs.

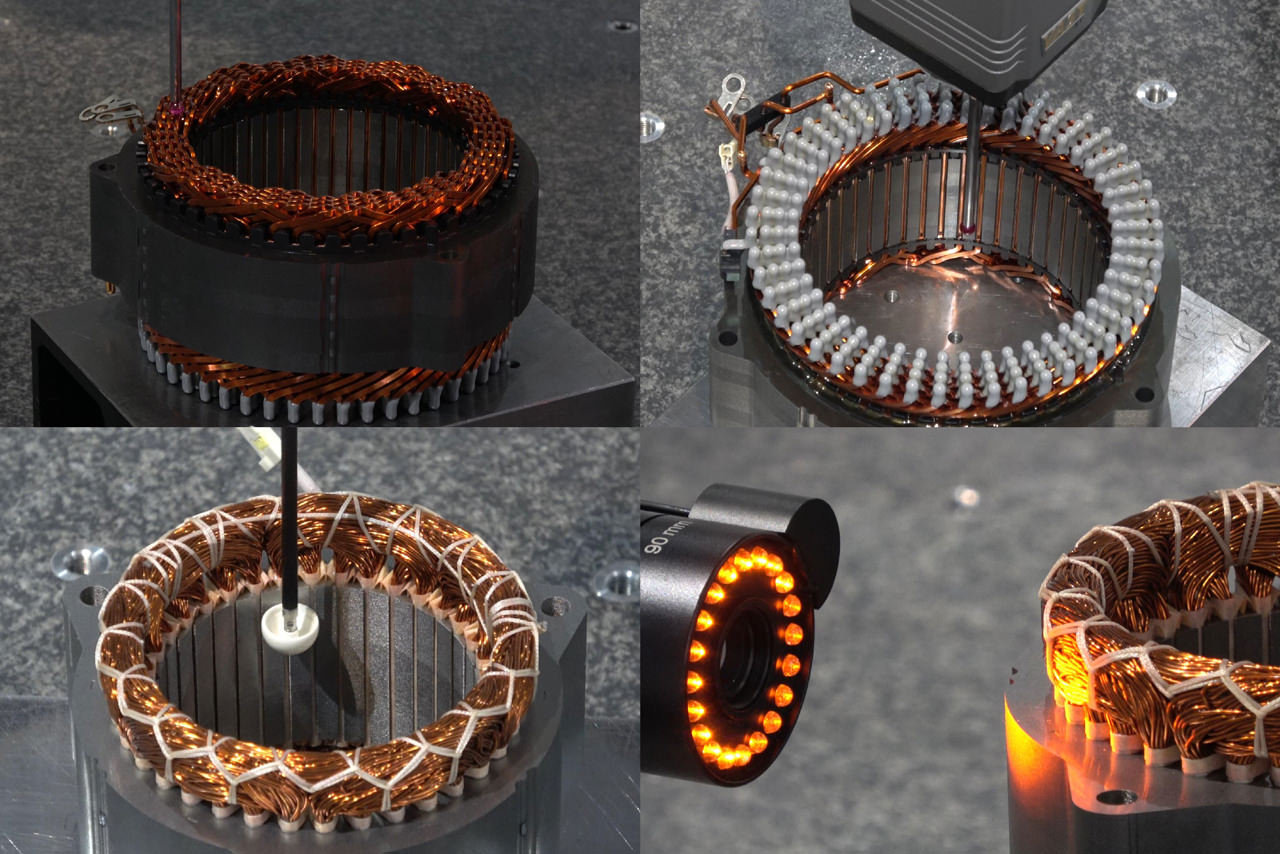

CMM Measurement in Production Processes of Drive Motors for EVs - Stators -

NEV (New Energy Vehicle) is the general term for vehicles equipped with systems producing electrical energy to supplement or replace conventional internal combustion engines. MHEVs, HEVs, PHEVs, and BEVs are all NEVs utilizing motors as part of their power train. In particular, the drive motor which generates power is positioned as a major system component of NEVs, and the accelerated development and increased production volume of drive motors are apparent. For example, the production process of hairpin stator, a key component of drive motor, is extremely complex. In many cases, a CMM equipped with contact and/or non-contact sensors is used to measure dimensions and shape for process control and quality assurance purposes. In the stator sheet stacking process, three-dimensional analysis of twisting, tilting and other features of stacked sheet is important. The high-accura CMM, ZEISS PRISMO, is optimal to measure the internal diameter of the stacked core due to its ability to measure continuously by scanning while avoiding (jumping over) notched area. Moreover, ZEISS DotScan, which is a white light interferometric distance sensor, is useful to evaluate flat type wires after bending process and can capture the shape of these wires using a non-contact method ensuring no damages on the coating. Furthermore, for the dimensional evaluation of height, I.D., and O.D. of stator assembly, the active scanning probe, VAST Series, can obtain values accurately. ACCRETECH offers optimal solutions for the production processes of NEV motors.

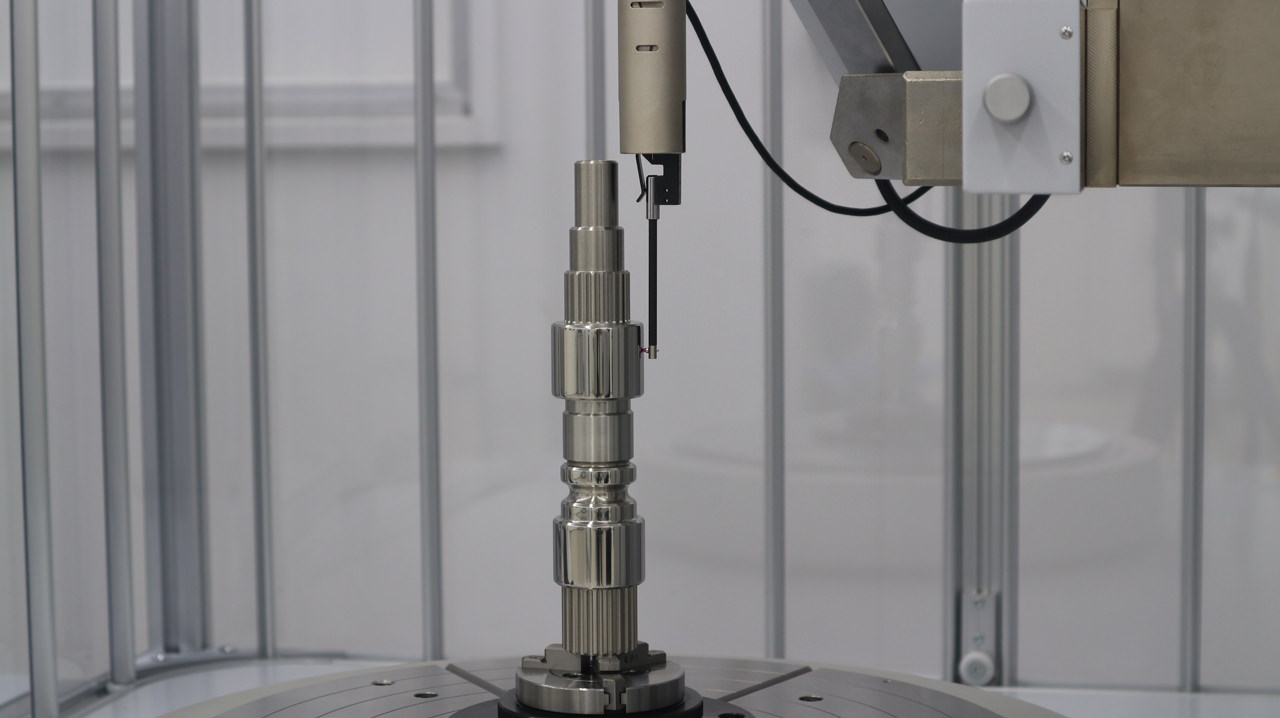

Evaluation of Cylindrical Components in Production Processes of Drive Motors for EVs - Rotors & Shafts –

Generally stator and rotor are located in a motor with minimal clearance, and the smaller clearance and less eccentricity make better characteristics of a motor. Moreover, in order to further enhance a motor the shaft supporting the rotor should be lighter, quieter, and capable of higher-speed rotation, therefore analysis of roundness, coaxiality, and concentricity at the component level is important. CMMs and roundness/cylindricity measurement machines are effective to measur the cylindricity and coaxility of a rotor’s O.D. and a stator’s I.D. For example, RONDCOM CREST is an ultra-high-accuracy model of a roundness measurement machine having a rotating accuracy of 0.01 μm in both the radial/axial directions. This makes it one of the most accurate machines in the world and an optimal solution for measuring ultra-high-precision components.

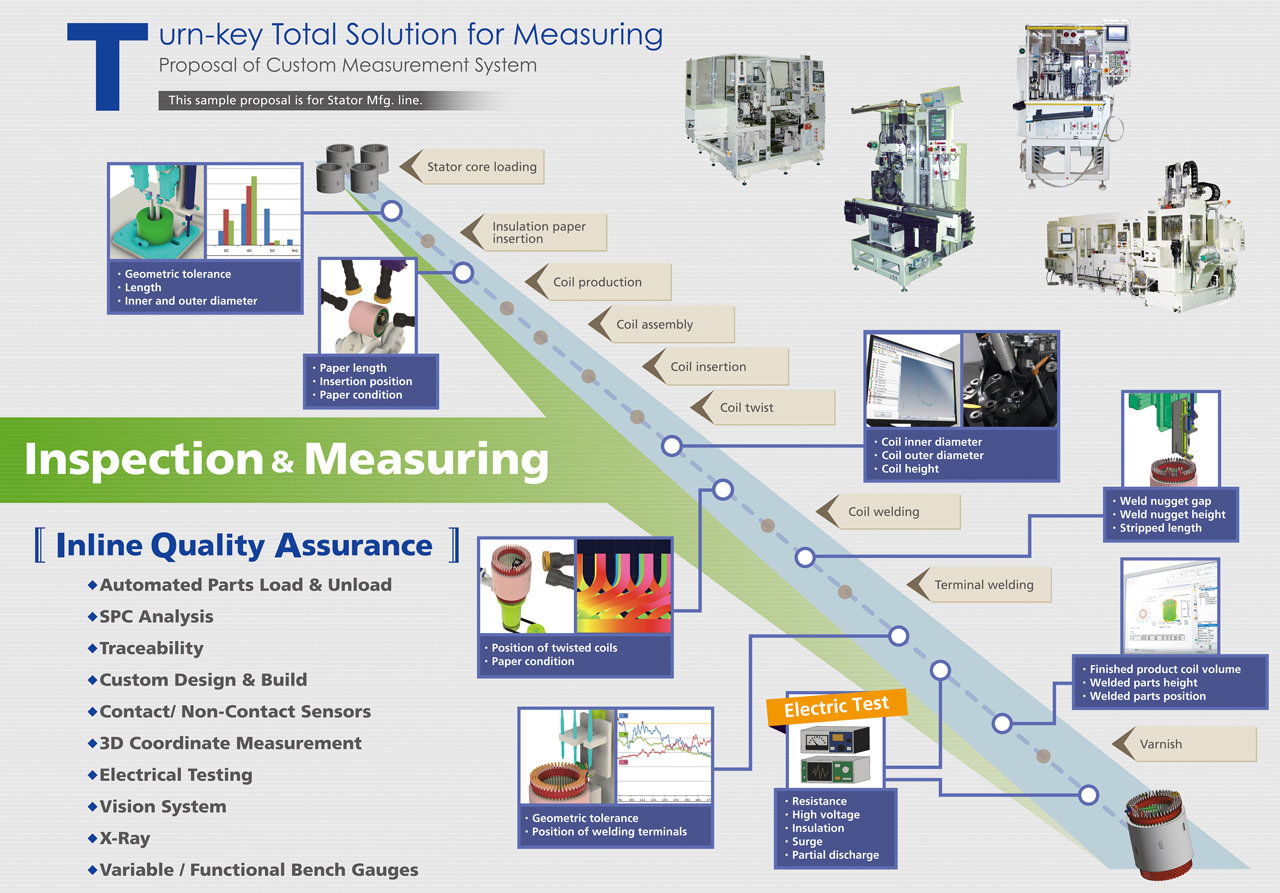

Customized Automatic Measuring Equipment Suited to Motor Production Processes

In the electrification of vehicles, specifications of motors adopted in BEVs, HEVs, etc. vary greatly, and the manufacturing processes of components are also different among motors. Moreover, due to the industry comprising both traditional automakers and start-ups, the manufacturing systems, production line configuration, and the extent of automation also varies significantly. Leveraging our technical capabilities forged from delivering over 1600 customized automatic measuring machines for ICE vehicles over a period of 70 years, ACCRETECH proposes optimal and flexible solutions for all production processes of EV motors. In addition to the general-purpose measuring instrument for hairpin stators as mentioned before, we propose customized special measuring instrument suiting customers’ needs for everything from insulation paper insertion to coil manufacturing, welding, and varnishing processes. Our measuring instrument has many applications, such as contact-type/non-contact type (e.g. image analysis) measurement, and electrical characteristic tests. ACCRETECH’s integrated proposals covering the overall production process eliminates the cumbersome task of the customer placing requests to multiple measuring instrument manufacturers and simplifies the centralized management of data, such as SPC and traceability.