ZEISS CONTURA

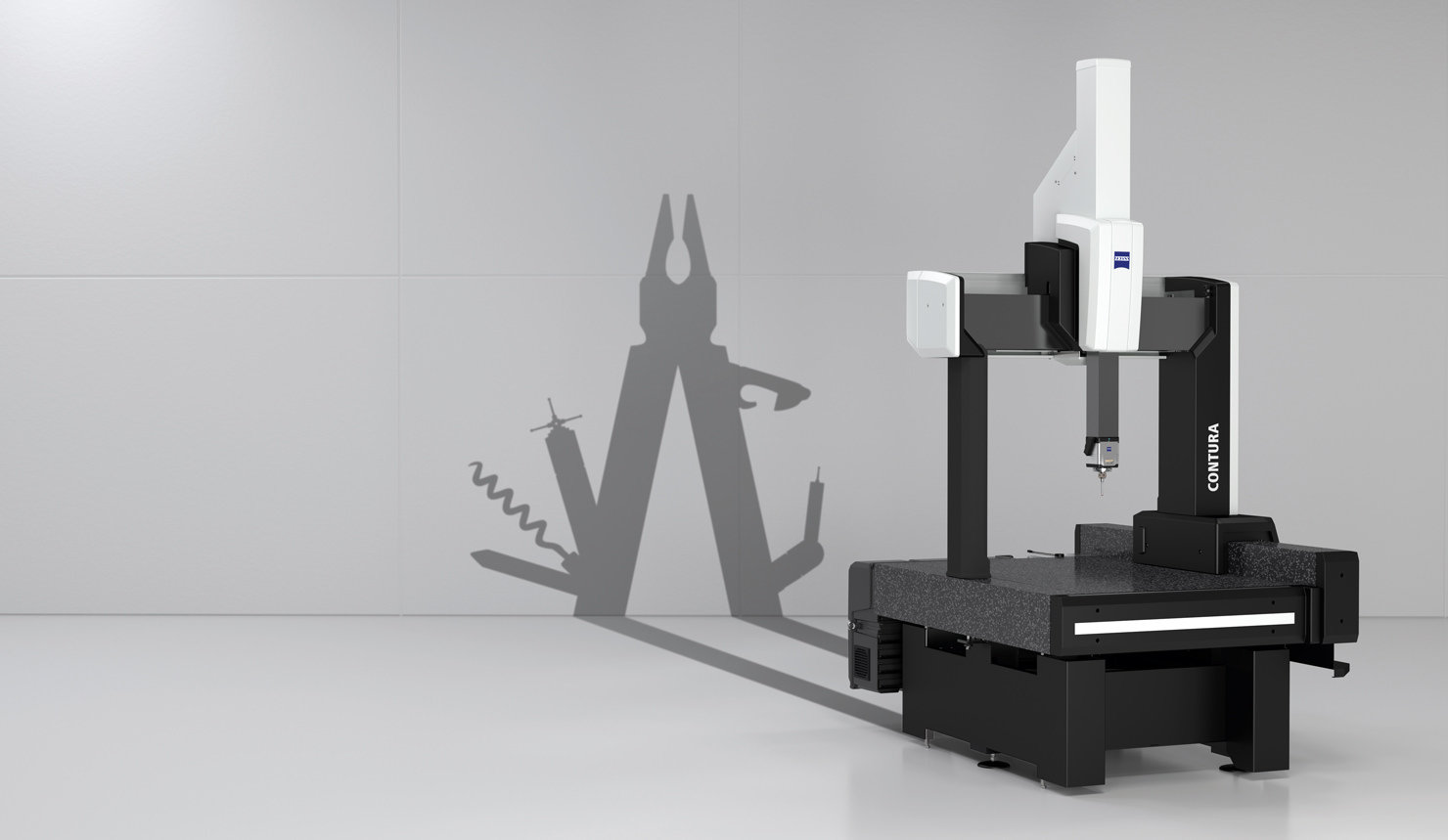

ZEISS CONTURA is a high-performance CMM by Carl Zeiss offering absolute diversity and flexibility. Equipped with ZEISS' multi application sensor system (mass) technology, it supports all kinds of applications while swiftly and easily switching between various sensor technologies as a multi-tool instantly adapting to customers’ ever-changing requests.

ZEISS CONTURA

Prepared for all challenges - today and tomorrow - A high-accuracy, high-performance CNC CMM

There are many decisions to be made when introducing a new measuring machine. It is difficult to predict all measurement requirements that may arise in the near future. With ZEISS CONTURA, however, there is no need to worry about this and that in advance. “Mass” technology, which allows various sensors to be used at will, supports a wide range of applications in one machine, in regards to both contact and non-contact measurement. ZEISS CONTURA offers flexible operation. For example, cost can be kept to the minimum in the beginning by only featuring the specifications the customer needs “now,” then sensors can be added later on if required due to new measurement styles in the future. We also offer innovative options such as 4-axis (X/Y/Z axis and RT rotating axis) measurement using the RT-RB rotary table, automatic probe replacement system ProMax E, and High Temperature Grade (HTG) to meet your diverse needs.

Flexible

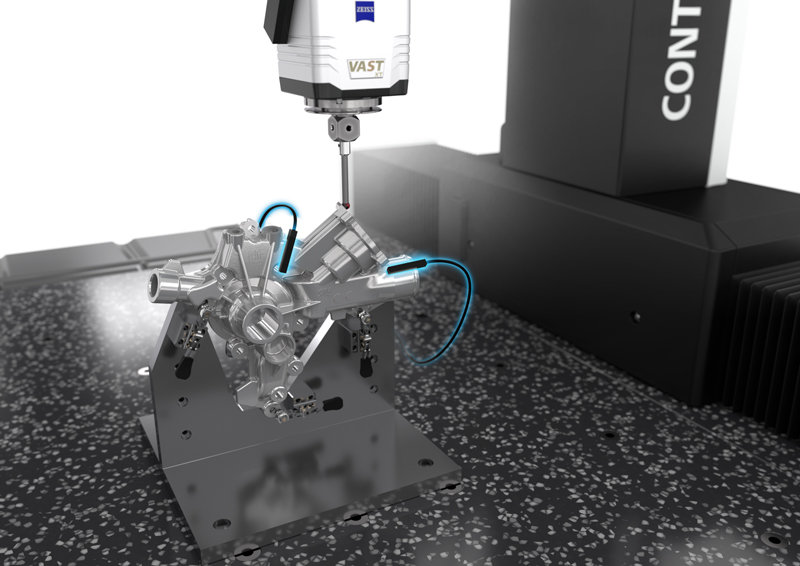

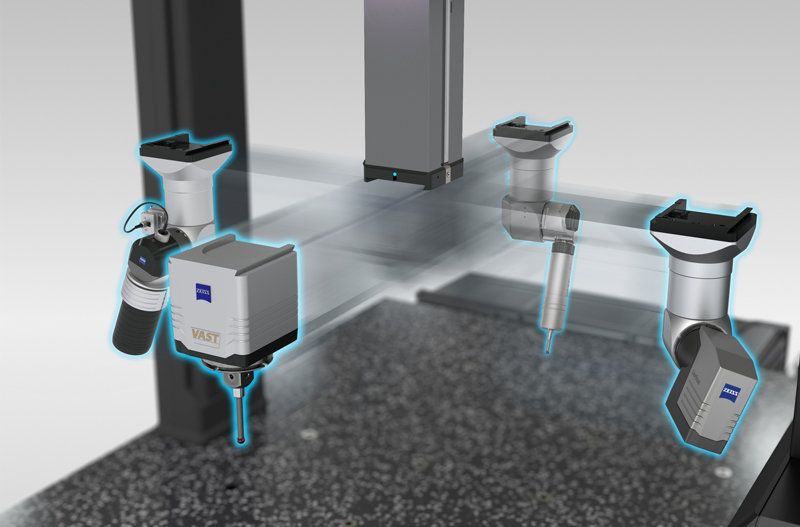

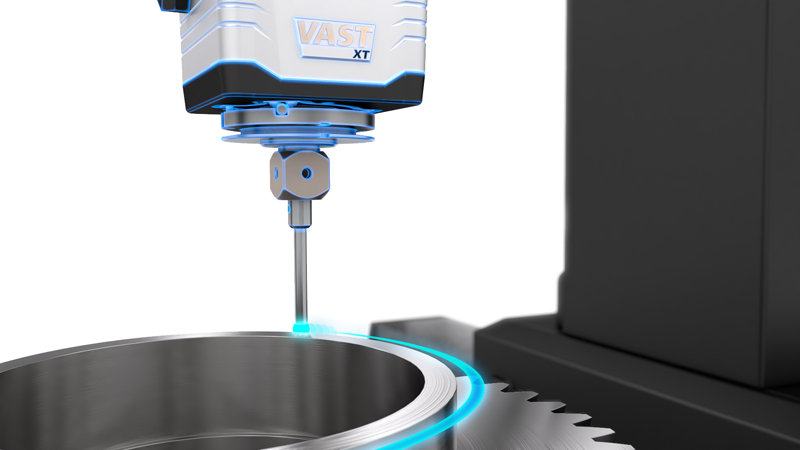

ZEISS’ multi application sensor system (mass) technology allows for the optimal combination of sensors from active/passive scanning, laser sensors, camera sensors, and white light distance sensors. Customers can measure workpieces while freely switching between multiple sensors to best suit the workpiece type/shape, and evaluation item. For example, an active scanning probe is best when measuring workpieces with notches or gears, while a non-contact camera sensor is best for measuring the width of extremely fine grooves and small holes, which are difficult to measure with contact-type methods. The new CONTURA is like a multi-tool that can instantly respond to a variety of applications and the ever-changing needs of customers.

Reliability

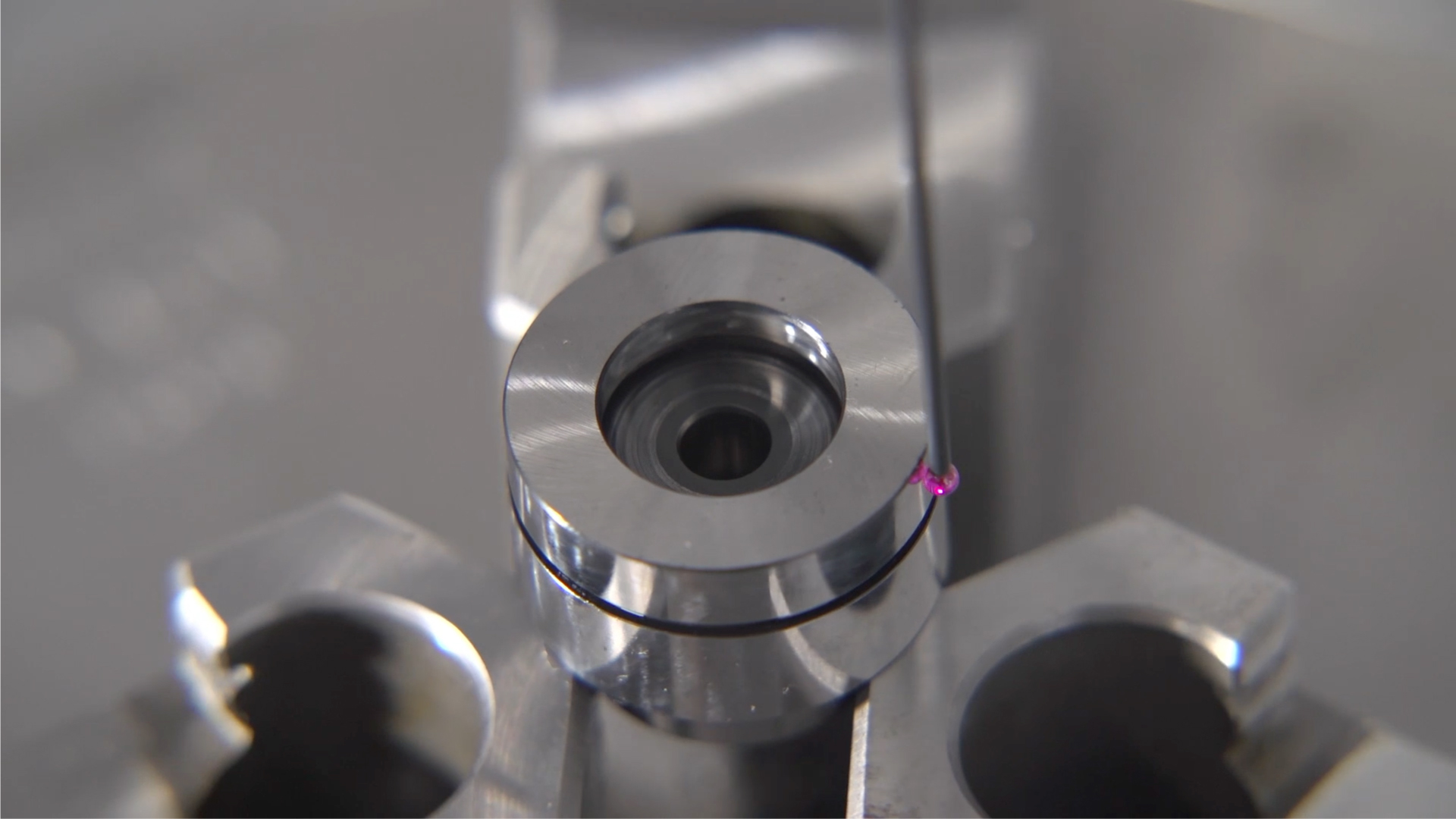

ZEISS CONTURA has an extremely high resolution of 0.08 μm, which is by far the highest resolution in its class and has a glass ceramic scale with extremely small thermal expansion and contraction on each axis. In addition to the scales themselves practically not expanding or contracting at all, this machine adopts Carl Zeiss' unique scale floating retention system, which prevents the scale being affected by the expansion and contraction of the guide resulting from temperature change. This eliminates the adverse effects of temperature change on measurement results and further enhances the reliability of measurement.

User-friendly

A foot space is provided on the front of the frame, making for a user-friendly design preventing the operator from hitting their knees on the front of the measuring machine. There is also a holder and rail for the operation box on the front of the plate, allowing the user to move the operation box freely into a position where operations are always easy to perform. Users can make the most of the measurement range without having to place the operating box within the measurement range on the plate during CNC measurement. This creates a comfortable working environment in limited space.

Option

Rotary Table RT-BR 100

A total of four axes – comprising the three axes of the measuring machine itself and the rotating axis of the rotary table – are synchronized to achieve high-accuracy, high-speed scanning measurement. The full circumference of the workpiece can be measured with a small stylus configuration, greatly reducing the frequency of stylus changeover. This shortens measurement time and reduces stylus costs.

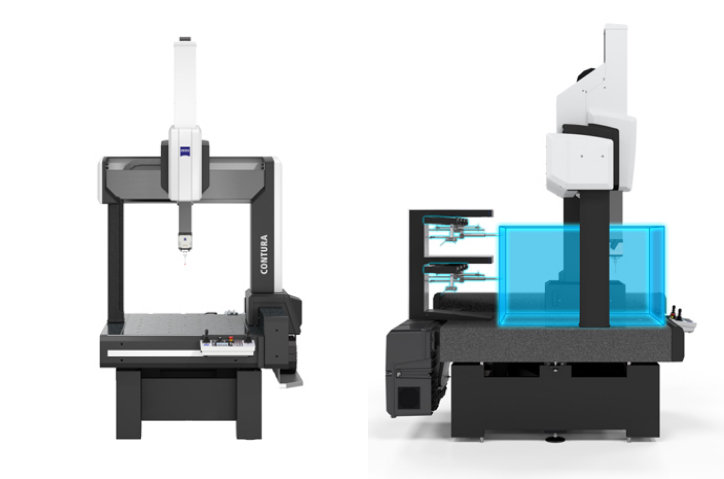

Automatic Probe Replacement System -ProMax E

Typically, when using a CMM, the storage for changing styluses is located within the measurement range, but in the case of ProMax E, this is placed outside the measurement range and moved within the measurement range only when the stylus is being changed. The stylus can be changed safely while ensuring the maximum measuring range without interfering with the workpiece’s installation space.

HTG(High Temperature Grade)

By covering the right Y-axis guide, the impact of dust and temperature change is minimized, thus further raising the reliability of measurement results. Moreover, combined with the temperature offset effect of the workpiece temperature sensor included in the HTG option, the temperature range extends from the normal range of 18 to 22 degrees Celsius to 18 to 26 degrees Celsius without altering the guaranteed accuracy. HTG is an optional function with the advantage of reducing running costs necessary for the temperature control of measurement rooms.