XYZAX Opt-BLISK

The expanding global aircraft market demands authentication and certification based on international standards, as well as stringent quality control of components. In recent years, measuring technology cultivated by ACCRETECH has supported everything from the development to the production of aircraft components, including engine components, which are improving in performance.

XYZAX Opt-BLISK

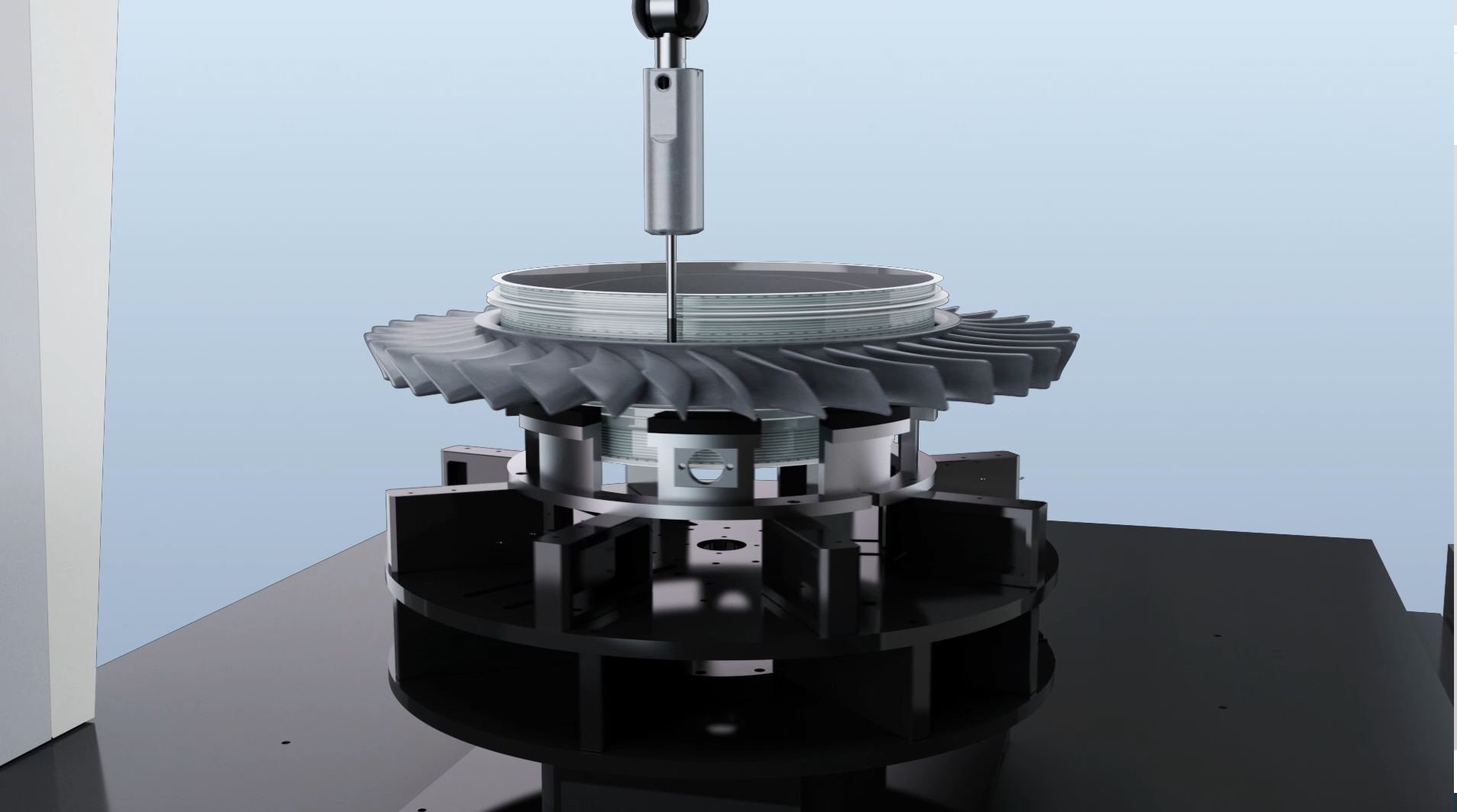

Development of “Opt-Blisk”–A Non-contact Blisk Measurement Special-Purpose Machine

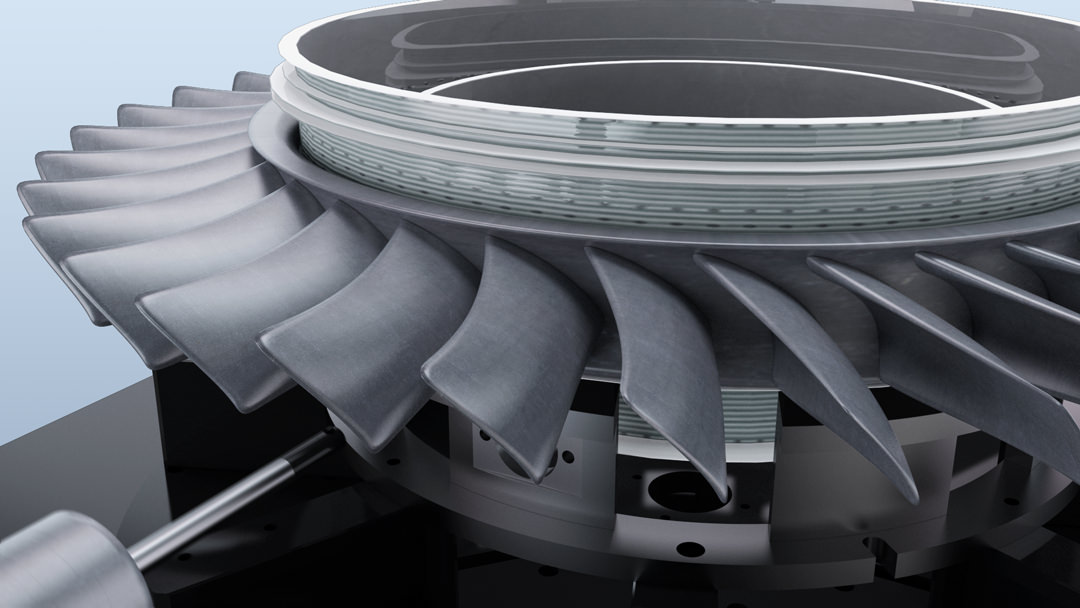

There is a rising demand for measurement of “blisks," a component of aircraft engines formed by the integration of rotor disc and blades. The integrated structure of a blisk offers advantages such as fewer parts and less material weight, however, due to its complex structure, a more advanced form of measuring technology is required. Sensors and styluses able to reach the detailed portions where blades overlap are essential for measuring blisks, and contact-type sensors have played a role in such measurement until now. While a wide variety of styluses can be attached to a contact-type sensor for flexible measurement, it is necessary to consider the deflection of the stylus caused by measurement pressure and friction, as well as the measurement speed from the sharp shape of the blade edge, therefore reducing measurement time is a major challenge. In light of this, Tokyo Seimitsu developed a non-contact blisk measuring machine, “Opt-Blisk.”

Reducing measurement time through high speed and high acceleration

Opt-Blisk is a special-purpose blisk measuring machine created by combining technologies cultivated in the development of Tokyo Seimitsu's CMM and non-contact, high-accuracy rotating probe. It is easy to increase the speed of non-contact measurement as there is no need to consider the effects of measurement pressure or stylus deflection, however, it is necessary to maintain sensitivity by applying the measuring beam perpendicular to the freeform surface of the blisk blade portion designed based on fluid dynamics. Opt-Blisk's unique measuring path generation technology and 4-axis synchronization control of the XYZ axis and rotation probe enable high-speed scanning along optimal paths whilst maintaining sensitivity, even in blisks with narrow portions where blades overlap. By combining AXCEL, a high-acceleration CMM, with a non-contact, high-accuracy rotating probe, measurement time has been reduced by approximately 60% compared to conventional contact-type sensor measurement.

Non-contact rotating probe enables flexible and speedy measurement.

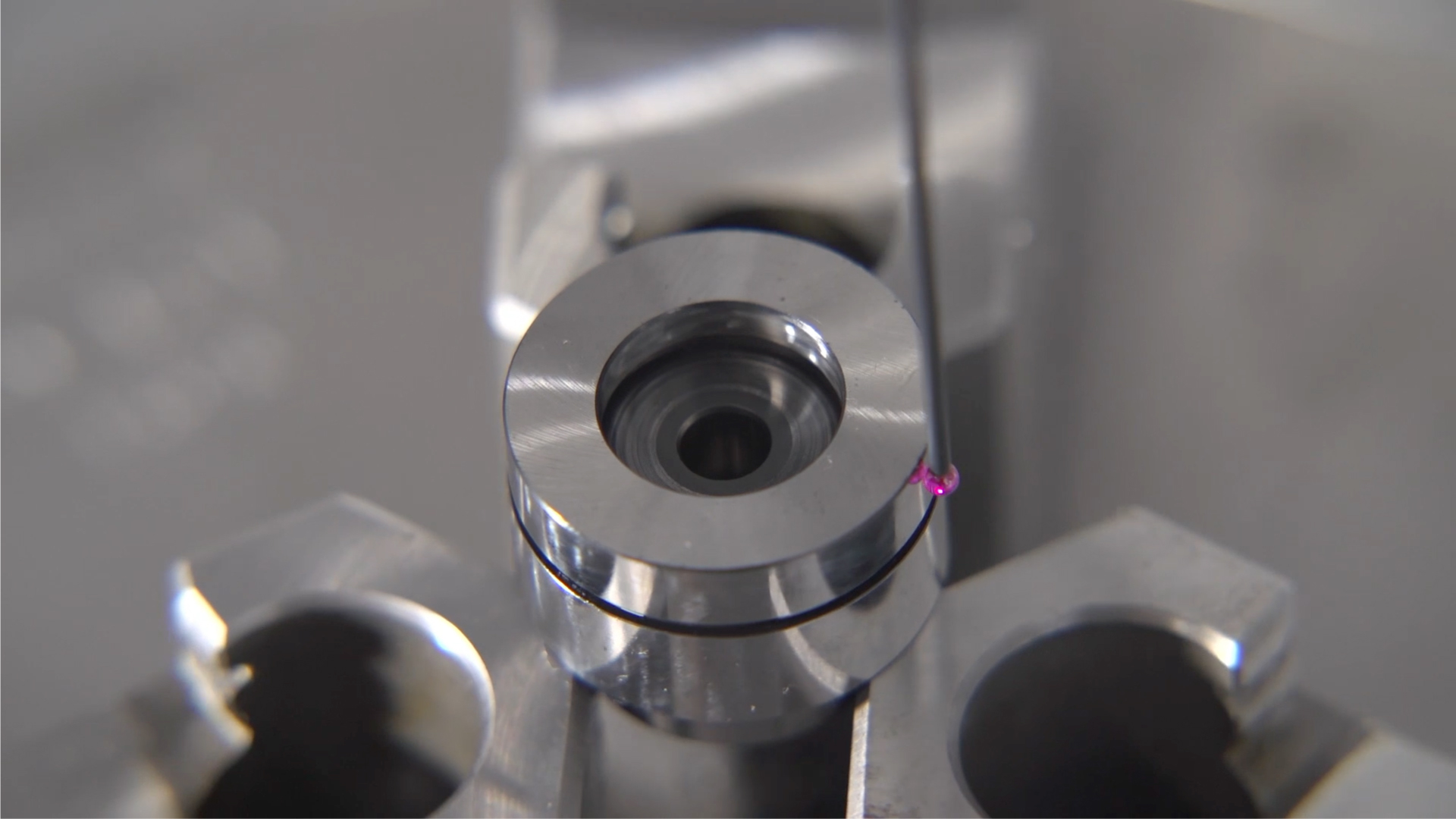

Opt-BLISK incorporates the non-contact displacement sensor technology that ACCRETECH has developed and applied as a probe for 3D coordinate measuring machine. The probe can enter the narrow gap between the blades and measure the profile of the workpiece while the measurement light is directed normal to the surface. The probe tip can be rotated 360°. By synchronously controlling this rotation mechanism and the four axes of the 3D coordinate measuring machine, the direction of the measurement light can be optimized even for the edge of the blade, enabling flexible and speedy measurement while maintaining sensitivity.